SINCE 1997,HNA has been an integrated engineering & manufacturing specialist recognized worldwide for its unique HIGH PRESSURE FORGING, WORLD TOP CLASS HEAT TREATMENT, PRECISE MACHINING Technology and high quality products in the O&G industry, by designing and fabricating HNA Valve Seats-- One-Piece Forged with Full Open, Cage Valve Seat Design for Triplex and Quintuplex plunger pumps, which are 100% interchangeable to most of the global famous brands: Halliburton, Weir SPM, Gardner Denver,Oilwell, FMC, OFM, Cooper OPI, SJ, Serva, JR, SANY & other major types of models, and customized design and production available.

Features:

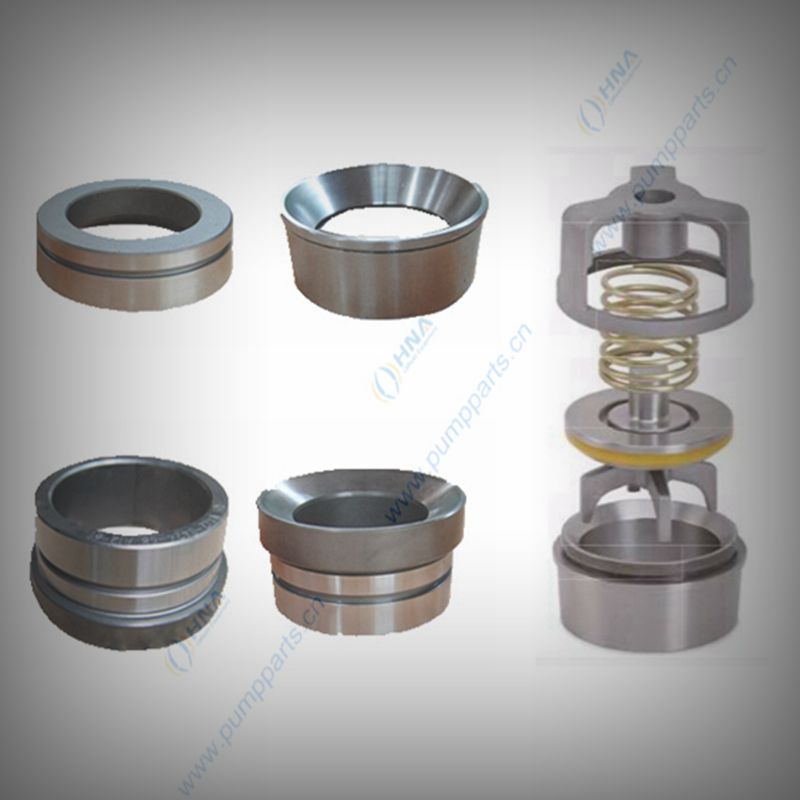

* High Pressure Forged One-Piece integral valve seat

AISI 8620(20CrNiMo) AISI 8620H(20CrNiMoH) AISI 4119(20CrMnMo)

(Or customized material)

* World Top Class Heat Treatment & Carburizing Technology ensuring best mechanical properties (Tensile, Yield, Charpy Impact, Elongation etc, with surface hardness 60-65 HRC) and Temperature & Corrosion Resistance Performance Exceeding API Standard for extended service life

* World Top Class Precise Machining Crafts offer high precision machined components for a close tolerance fit. Special care is taken for the dimensional matching of the valve seat and body working angle for ensuring longer service life even under extreme working conditions

* HNA’s valve seats are the API standard for cementing & fracturing media such as sand and man-made resin-coated sand proppants. The seat gives unparalleled performance in the most extreme conditions like pumping high-strength ceramic proppants or sintered bauxite proppants at pressures above 15,000 psi while withstands rates in excess of 1,000 SPM

* Full Open, Cage valve seat types specifically designed to match with Bottom Guide Type 4 Wing, 3 Wing, and custom designed valve body.

* Precisely tapered design of the insert matching with the valve body provides evenly distributed loading characteristics and therefore ensures better sealing performance.Double angle 55°, 45°, or other specified taper design available to match with different valve type, pump type and applications.

* API Valve Seat and Non-API Modified Valve Seat Available. While matching with HNA valve, HNA Valve Seat offers large metal-to-metal bearing area surface, even loading of the seat deck in the fluid end module, and therefore promotes longer service life and maximum fluid flow

* High Extrusion/Abrasion Resistance:Extremely Perfect

High Chemical/Corrosion Resistance: Extremely Perfect

High Pressure Resistance: Maximum 15,000 Psi

* Extremely Long Service Life Far Exceeding API Standard

* Fully interchangeable with Mission Service Master Drilling, Service Master II Valve Seat,Novatech Cast-N-Place Valve Seat, SPM 2.0 Valve Seat, and other major valve seat types,available in API 3# thru API 9# sizes, and Non-API Modified Type & Sizes

* Product Series:

HNA-PF-S-FO : HNA Valve Seat,for plunger/frac pump -- One-Piece Forged, Full Open, Available in API 3# thru API 9# sizes, and Non-API Modified Type & Sizes

HNA-PF-S-CG : HNA Valve Seat ,for plunger/frac pump -- One-Piece Forged, with Valve Cage, Available in API 3# thru API 9# sizes, and Non-API Modified Type & Sizes

Customized Specific Design & Series of HNA Valve Seat,for plunger/frac pump -- One-Piece Forged, API/Non-API Standard

Position:

Position: